The popularity of natural floor materials – and a desire to ‘bring the outside in’ – is showing no sign of slowing. Along with limestone and timber, there’s also renewed interest in terracotta – and not just in traditional settings. Its rustic good looks bring a real warmth to all interior styles and, with earthy tones flagged as a major trend this year, demand looks set to increase even further.

Terracotta is a very wholesome, natural material. It’s basically clay that’s dried in the sun or fired in an oven and the name literally means ‘baked earth’. Along with its beautiful burnt orange colouring, terracotta provides a robust finish that’s versatile and easy to look after. However, like many natural materials, it is porous and can easily become stained. There are two ways of protecting terracotta tiles – either by applying a synthetic sealer or the more traditional method using Boiled Linseed Oil and wax.

The two ways to protect terracotta:

Synthetic Sealers

Synthetic or acrylic sealers are the easier option in terms of application. They’re generally faster to apply and they create a surface seal with a degree of sheen. LTP options include Colour Intensifier & Stain Block – a non-film forming impregnating sealer that fills the pores of the tile. This treatment can be used on its own, for a natural finish, but we recommend a follow-on application of LTP Ironwax, to make tiles easier to mop and keep clean. LTP Ironwax is a film forming sealer that creates a self-shine surface layer; it is applied with a sponge or paintbrush to textured tiles, or with a cloth or pad to honed tiles, and no buffing is required. Three coats are generally sufficient – with an hour between each application – but a higher sheen can be created with additional coats, up to a maximum of six.

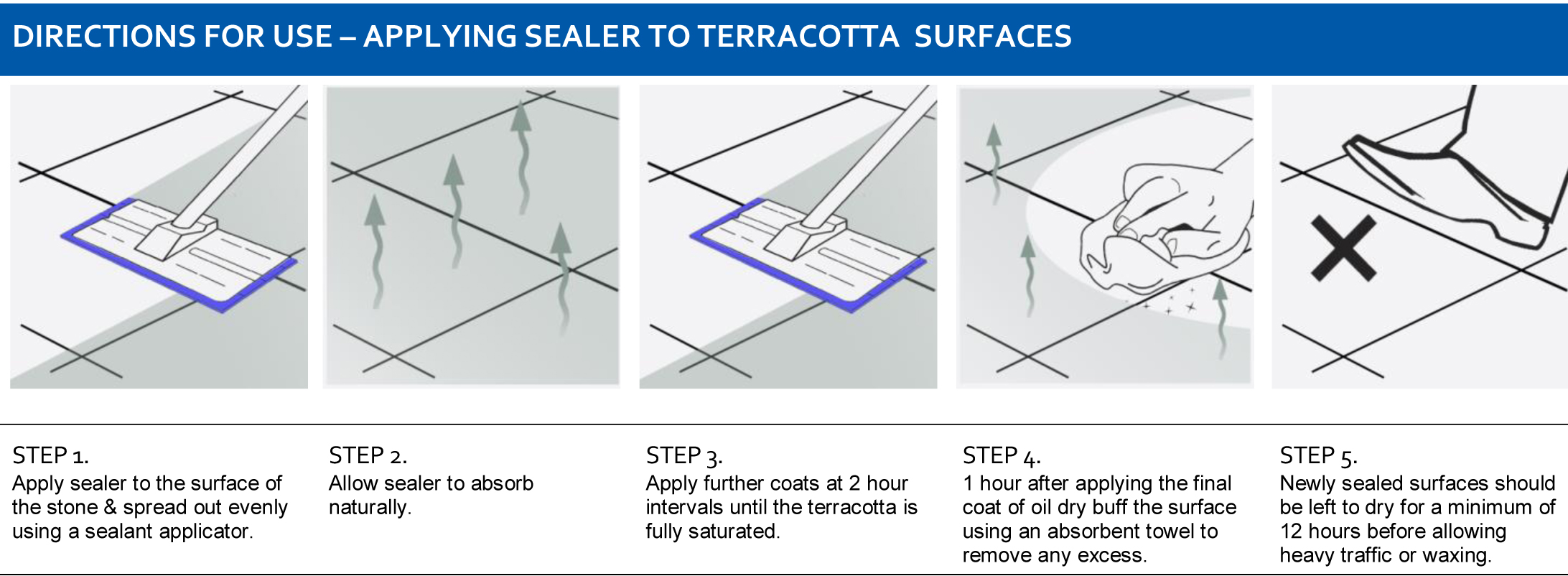

LTP Colour Intensifier is also applied with a sponge, pad, cloth or brush and left for 60 minutes between coats. For a strong colour tone and for more absorbent material, further coats can be applied after 60 minutes. All terracotta’s have different levels of porosity, so there is no specific recommendation regarding number of coats. The best advice is to apply the sealer, as instructed, until the tile is fully saturated, ie., an even layer of sealer is still visible on the tile surface 30 minutes after application. The tile should be left to dry and then gently buffed to remove any excess, if any remains.

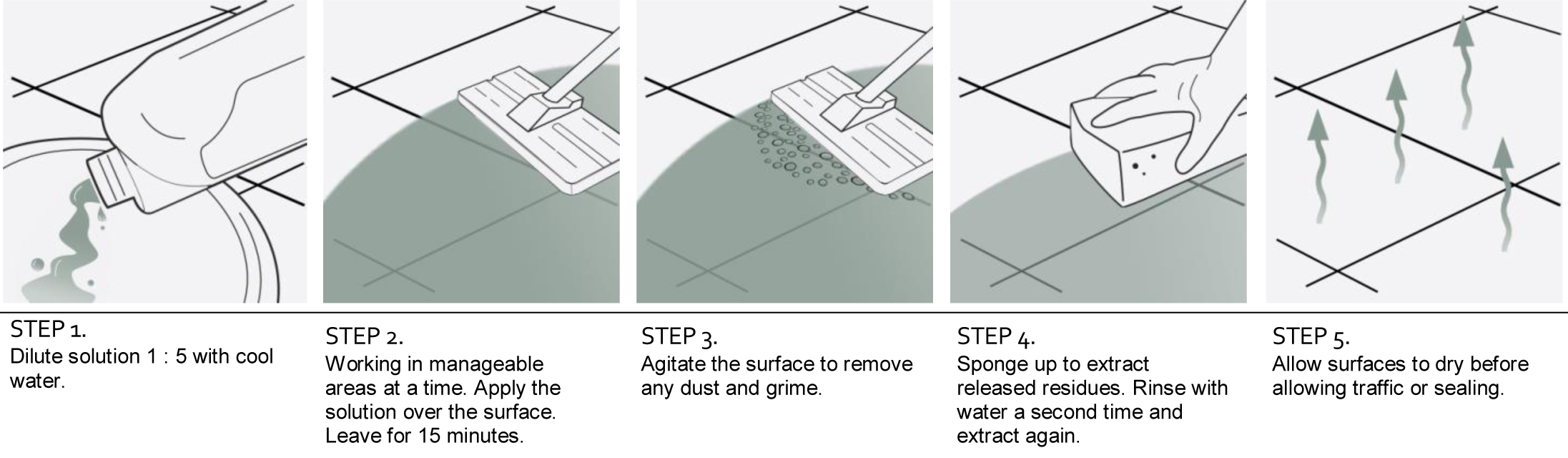

Before any treatment is applied, tiles should always be cleaned thoroughly, to remove all dirt and grout residue. For ongoing cleaning and aftercare, use LTP Floorshine, which reinforces protection as it cleans.

The Traditional Method

Although the traditional treatment route takes longer, it does create a more characterful aesthetic and it gives the terracotta longer-term mechanic strength, by effectively filling the pores. This YouTube video show installation and treatment of hand-made light terracotta, with a further demo below.

During the first stage of treatment – and following a thorough clean – LTP Boiled Linseed Oil is applied with a brush until the tiles are saturated. You should allow at least 12 hours between each coat to ensure that the oil thoroughly cures. Most terracotta will take 1-2 coats to reach saturation but some tiles, especially handmade terracotta, may take 4-5 coats. The tiles should then be left to dry for at least 24 hours.

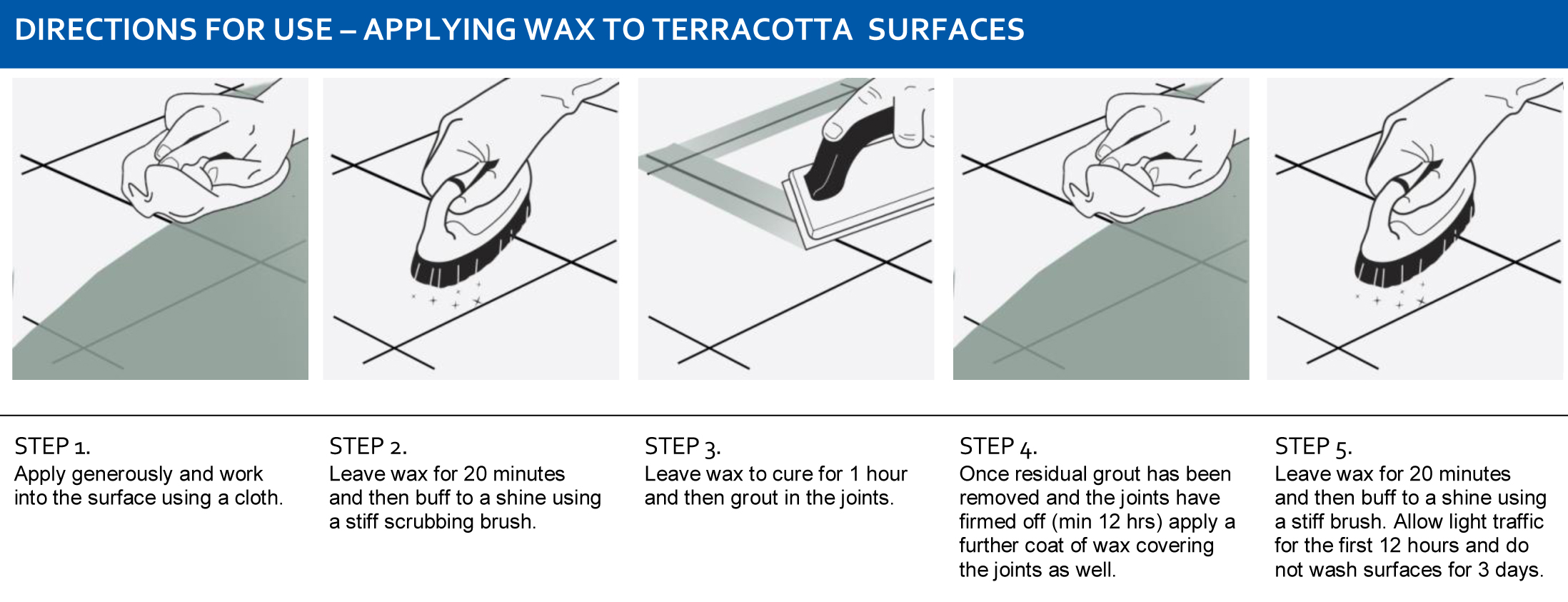

During the second stage of treatment, wax is applied. This provides a resilient protective layer against water, dust and dirt, as well as extra sheen. LTP treatments include LTP Clear Wax – a natural, clear finish – and medium brown LTP Antique Wax which deepens the colour tone and, in many cases, instantly ages the appearance of the terracotta. Both treatments have a soft paste consistency. They are applied with a cloth and the surface is then buffed. The traditional treatment method can also be used to restore older floors, once the tiles have been thoroughly cleaned and any existing sealant removed.

For ongoing cleaning and aftercare, we recommend LTP Waxwash – a gentle, pH neutral cleaner which contains a trace of Linseed Oil to reinforce protection.

For more advice on floor maintenance and protection, please contact LTP’s Technical Team on tel. 01823 666213, email info@ltp-online.co.uk or visit http://www.ltp-online.co.uk

ends –

For further media information and photography, please contact:

Angela Fitzhugh PR Ltd at angie@afpr.co.uk or tel. +44 (0)1579 673026.